Discover the Acea Group online 2019 Sustainability Report

Environment segment – waste management overview

SCOPE OF REFERENCE

The chapter includes the activities of the waste treatment hub, the waste-to-energy plants, the compost production plants and Aquaser, all in Acea Ambiente.

In line with the European vision of the Circular Economy, Acea manages the waste cycle in order to recover, recycle and reuse waste in the best possible way and, when possible, recover energy. The Group, in particular, occupies itself with the following phases of the waste cycle:

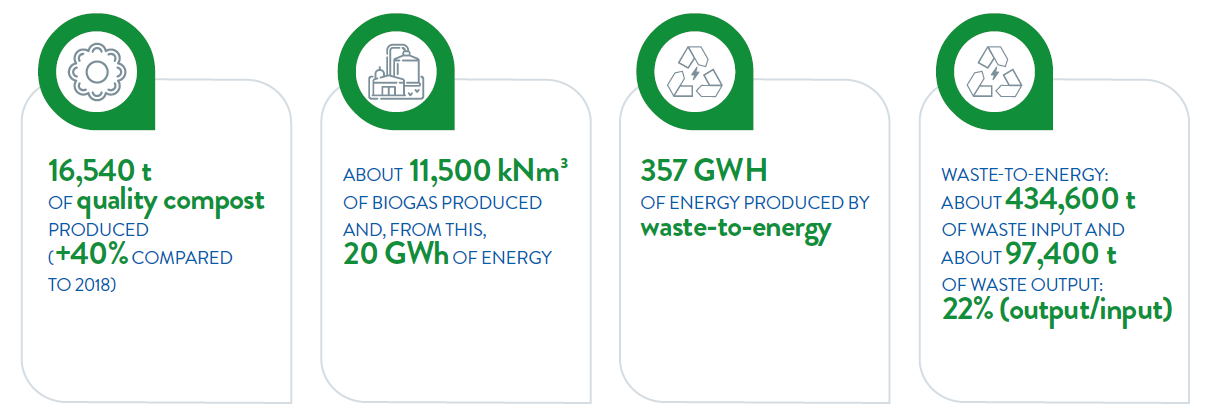

- treatment of municipal solid waste (MSW) and other types of waste (like green waste from separate collection, industrial waste, etc.), for the recovery of material and disposal of only the residues in landfills;

- incineration with energy recovery with consequent reduction of the soil needed for disposal;

- production of high quality compost for agriculture.

Of importance for the company is also the issue of treatment and reuse of non-hazardous waste, and in particular hazardous waste that presents the greatest problems for disposal, not only in environmental and social terms, but also in economic terms, given the high cost.

In 2019 Acea developed the widespread composting project called Acea SmartComp (see the box below and also The commitment to research and innovation in the chapter Institutions and the company)

Acea SmartComp

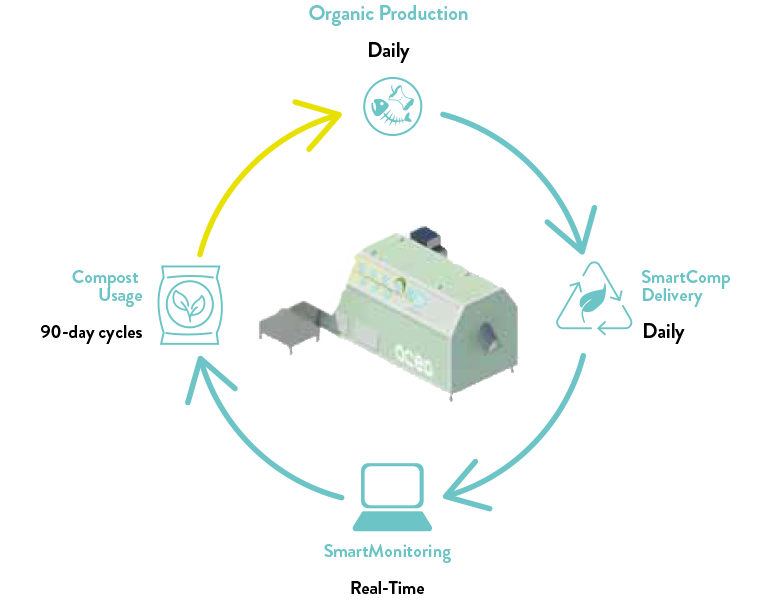

Acea SmartComp is an innovative solution for the transformation of organic waste into a product (compost), directly at the site where the waste is produced.

The project is inspired by the waste transition, a new model of zero km waste management based on a widespread and distributed network of mini-processing plants for the organic fraction.

Specifically, the composter is an accelerator of the aerobic degradation process of organic substances, and the compost produced, reduced in weight by up to 20% compared to the original treated waste, is a product that is naturally sanitized and ready for use as a soil conditioner.

The innovation of the process lies in the smart operating logic based on advanced sensors – algorithms and dashboards, prepared jointly by ENEA and the University of Tuscia – and smart remote control of the process, with the optimisation of ageing times, product quality and environmental impacts.

The advantages of the process are both financial, with reduction of waste collection and treatment costs, and environmental, with reduction of CO2 emissions associated with transport.

Strong interest has been expressed by large food distribution and by big companies for the use of the composter in company canteens, and commercial initiatives launched in 2019 have led to the signing of a commercial agreement with Fiera di Roma and contracts with other entities and distribution companies.

Acea installed the first SmartComp at the canteen in its own headquarters and uses the soil conditioner produced in its green spaces, thus reducing the use of other types of fertilizer.

The following paragraphs provide further information on the operating aspects of the activities already mentioned and carried out in terms of waste management. These are modern plants, that have recently been revamped or expanded to improve and renew the processes and recover matter and/or energy where possible, and the use of advanced technologies necessary to improve the efficiency of waste management.