Discover the Acea Group online 2019 Sustainability Report

Sewerage service and treatment system

SEWERAGE SERVICE AND TREATMENT SYSTEM

The integrated water service (IWS) includes the management of the sewerage and treatment system. The water resource, after uses for the various civil purposes, is collected through the sewer pipes and sent to the purifiers. There pollutants are removed via physical processes (filtering, sedimentation, flocculation) and biological ones (aerobic and/or anaerobic decomposition of the organic substance with bacteria).

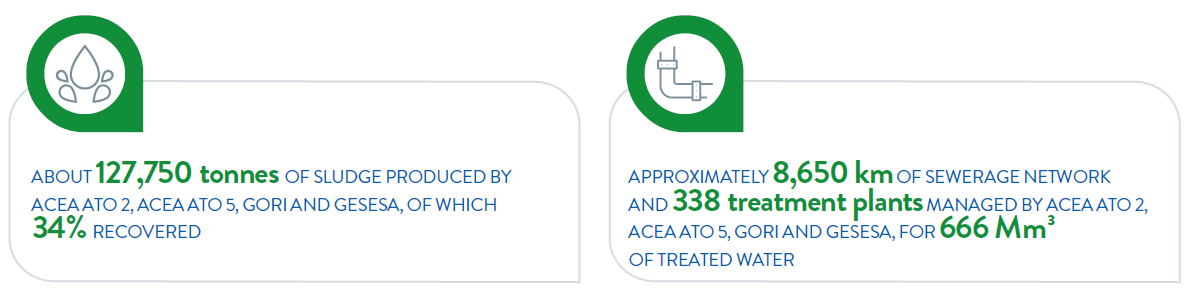

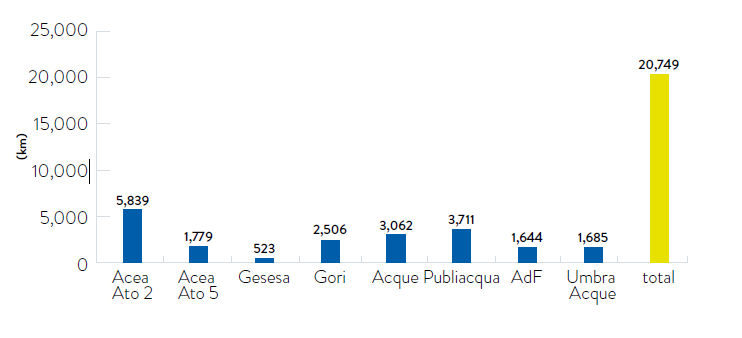

Thanks to approximately 896 treatment plants (of which 338 managed by Acea Ato 2, Acea Ato 5, Gori and Gesesa), the total volumes of water treated by the Group125 in 2019 were approximately 855 million cubic metres, of which 666 million cubic metres by Acea Ato 2, Acea Ato 5 and Gori126. The water in output from the plants cited, after having undergone the purification treatments described, has chemical and biological properties compatible with the life of the receiving body of water and in accordance with the values of the parameters which must not be exceeded in order to guarantee full compatibility (as per Legislative Decree no. 152/2006). The sewerage networks managed amount to about 20,750 km, of which 10,647 km relate to the four Companies cited.

CHART NO. 50 – SEWER NETWORKS OF THE GROUP IN ITALY (2019)

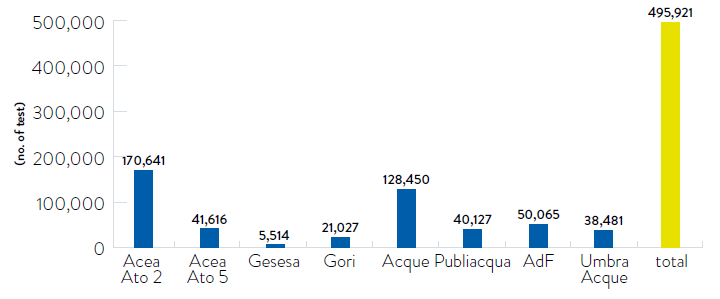

CHART NO. 51 – ANALYTICAL CHECKS ON WASTEWATER, TOTAL AND BY COMPANY (2019)

For Acea Ato 2, Acea Ato 5, Gori and Gesesa, the percentage coverage of the sewerage and purification services, out of the total users served by the water service, and the volumes of effluent treated are given in tables nos. 53 and 54.

In particular, for Acea Ato 2, the good abatement performance achieved in the purification process, which allowed approximately 600 million cubic metres of sewage to be made compatible with the receiving ecosystem, were confirmed by the over 170,600 calculations performed.

TABLE NO. 53 – PERCENTAGE COVERAGE OF THE SEWER AND PURIFICATION SERVICES OVER THE TOTAL UTILITIES OF THE WATER COMPANIES OPERATING IN LAZIO AND CAMPANIA (2017-2019)

| Company | 2017 | 2018 | 2019 | |||

| sewer | purification | sewer | purification | sewer | purification | |

| Acea Ato 2 | 91.7% | 88.0% | 91.6% | 88.2% | 91.5% | 88.1% |

| Acea Ato 5 | 67.7% | 56.5% | 66.9% | 56.1% | 66.5% | 55.9% |

| Gori | 79.9% | 57.3% | 82.2% | 65.7% | 82.3% | 66.0% |

| Gesesa | 81.2% | 26.1% | 80.2% | 27.3% | 80.3% | 30.4% |

TABLE NO. 54 – VOLUMES OF EFFLUENT TREATED BY WATER COMPANIES OPERATING IN LAZIO AND AT BENEVENTO (2017-2019) (*) (Mm3)

| Company | 2017 | 2018 | 2019 |

| Acea Ato 2 | 553.6 | 582.7 | 599.8 |

| Acea Ato 5 | 21.1 | 21.2 | 21.3 |

| Gori | 9.0 | 7.7 | 45.2 |

(*) For the time being there are no flow meters at the entry of the purification plants managed by Gesesa.

THE NEW LABORATORIES AT THE MAIN PURIFICATION PLANTS IN ROME

In 2019, the renovation of 4 of the 6 laboratories owned by Acea Ato 2 was completed. The first to be inaugurated, in July, was the new laboratory of the purification plant in North Rome, followed by the other three inaugurations of the new laboratories located at the purification plants in South Rome, Ostia and COBIS.

The laboratories carry out activities to support the control of the operation and functionality of the systems, ensuring rapid responses according to management needs.

The Analytical Control Unit of Acea Ato 2 manages these infrastructures and for each treatment plant prepares a programme for the control of the management and quality parameters of the treated waste. In 2019 the following were analysed by the personnel in the laboratories:

- 31,336 samples, 13,874 on the water line and 17,462 on the sludge line;

- 135,940 parameters, of which 92,825 for the water line and 43,115 for the sludge line.

In the “historic” area managed by Acea Ato 2, which includes Rome and Fiumicino, the main purification plants treated in 2019 approximately 514 million of cubic metres of wastewater, a figure that has increased (490 million cubic metres in 2018). Considering also the smaller purifiers and the plants of the municipalities acquired in OTA 2 (a total of 169) a total volume of approximately 600 million cubic metres of wastewater treated, a very slight increase compared to 2018.

Table no. 55 shows the details of the main parameters from the main treatment plants of Acea Ato 2, Acea Ato 5, Gori and Gesesa. Other indicators of the efficiency of purification are described in the section Key environmental performance indicators – Water Segment of the Environmental Accounts.

TABLE NO. 55 – OUTPUT PARAMETERS OF THE MAIN PURIFIERS MANAGED BY ACEA ATO 2, ACEA ATO 5, GORI AND GESESA (2019)

| Acea Ato 2 | Acea Ato 5 | Gori | Gesesa (Benevento) | concentration limits in surface waters Legislative Decree no. 152/06 | |

| parameter | average values (mg/l) | ||||

| BOD5 | 4 | 4 | 11 | 11 | ≤ 25 |

| COD | 25 | 20 | 27 | 40 | ≤ 125 |

| SST | 11 | 6 | 14 | 29 | ≤ 35 |

| nitrogen (ammoniac, nitric and nitrous) | 6 | 6 | 7 | 1 | - |

| fosforo | 2 | 1 | 1 | 2 | - |

| output quantity (t) | |||||

| COD | 19,587 | 1,099 | 1,203 | n.d. (*) | - |

| SST | 10,267 | 424 | 661 | n.d. (*) | - |

(*) For the time being Gesesa has not installed flow meters so the data are not available.

The sludge produced during the purification process is mostly sent for recovery of material (see in Environment Segment, the paragraph Intermediation and transport of waste).

Numerous actions were carried out in 2019 to reduce the amount of sludge produced by the purification plants managed by the Group’s companies. In particular, Acea Ato 2 developed several experiments together with Acea Elabori, including the commissioning of the ozonolysis plant in Ostia, the dryer of the purification plant in North Rome and the initiation of anaerobic digestion at the purification plant in South Rome (see the box for details and also The commitment to research and innovation in the chapter Institutions and the company).

BIOMETHANE AS AN OPPORTUNITY FOR INTEGRATED WATER SERVICE OPERATORS

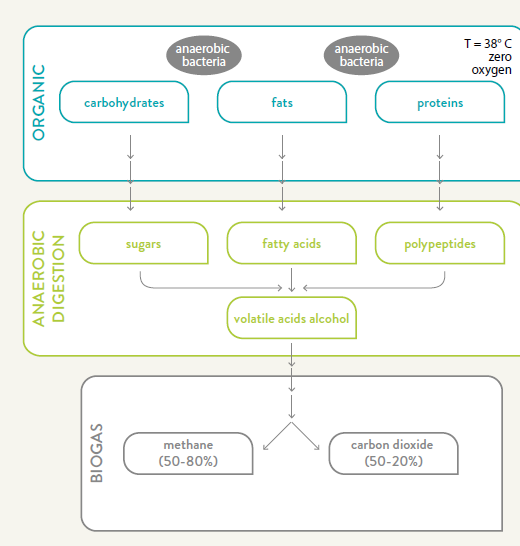

One of the most established methods of achieving sludge reduction is anaerobic digestion: at a temperature of about 38 °C and in the absence of oxygen, a bacterial strain is naturally selected from the sludge mass consisting of anaerobic micro-organisms capable of transforming the starting organic substance (carbohydrates, fats and proteins) into a mixture of methane (CH4) and carbon dioxide (CO2), called biogas.

The process results in a reduction of about 30-35% of the total sludge mass entering the treatment, enabling an easier and less expensive management of the sludge to be disposed of, and a production of about 35 Sm3 of methane for each tonne of sludge, with a consequent energy benefit.

Recently, a significant financial benefit was added linked to an incentive127 that rewards the transformation of biogas into biomethane and its subsequent use in motor vehicles, in compliance with strict sustainability constraints that must be certified by a third party.

The process of transforming biogas into biomethane is called upgrading, at the end of which the product obtained is almost completely free of substances other than methane (CH4 at about 98%), in particular carbon dioxide, present in the biogas of origin. It is eliminated along with other undesirable substances by filtration through special selective membranes.

The biomethane is suitable to be injected into the natural gas distribution network.

Acea Ato 2 is about to start the production of biomethane for upgrading biogas already available in the treatment plants in East Rome and North Rome, with a total annual production of about 2.5 million Sm3 and a corresponding abatement of about 25,000 tonnes/year of sludge.

In this perspective, the executive design phase of the two upgrading plants has already been completed, allowing the start of the qualification process at Gestore Servizi Energetici (GSE), the Public Body responsible for the proper management of the incentive, and the publishing of calls for tenders for the construction of technological works, including those necessary for the interconnection of the biomethane produced with the natural gas distribution network.

Among the many actions carried out by Acea Ato 2 aimed at mitigating the effects of parasitic waters128 in the sewerage system and improving the resilience of the systems to exceptional weather events, in 2019, 16 studies were completed that involved the verification of about 800 km of sewerage system present in the managed territory.

125 Again in this case, the data relating to the number of treatment plants, the volumes treated, the size of the networks and the controls refer to the main Group companies operating in the water sector, including those not included in the full scope of consolidation.

126 At the moment Gesesa does not have the flow meters so it is not possible to measure the quantities of wastewater treated in its purification plants.

127 With Ministerial Decree of 2 March 2018, which encourages the production of biomethane from the treatment of waste materials (sewerage sludge but also the organic fraction of municipal waste), Italy aligned itself with the requirements of the objective of the European directive called RED II – i.e. the Renewables Directive 2018/2001/EU repealing Directive 2009/28 – RED I: achieve a share of gross final energy consumption in the transport sector covered by RES of at least 14% (of which advanced biofuels > 0.2% by 2022, > 1% by 2025, at least 3.5% by 2030).

128 Parasitic waters are those that can enter the sewerage system and represent a component that does not conform – in terms of quality and/or quantity – to the size of the sewerage system. They can be from weather, surface water, groundwater, man-made (aqueduct losses, illicit connections, etc.).